RIGHT ANGLE AND OFF ANGLE GEARBOXES

CUSTOM DESIGNED AND CUSTOM BUILT

RIGHT ANGLE AND OFF ANGLE GEARBOXES

CUSTOM DESIGNED AND CUSTOM BUILT

What's your angle? If it is 5, 25, 42, 74, 90, 179 degrees or anything in between Curtis Machine has a gearbox solution for you.

Curtis Machine takes pride in it's design capability. Our engineers are able to take a customers concept drawing and turn it into a PRO-ENGINEER 3D solid model. Production programs are created utilizing PRO-MANUFACTURING, which takes the CAD model to create a CAM program. The CAM program is then utilized along with our state of the art CNC machines to generate prototype gearboxes.

Our most popular gearbox designs are right angle. Spiral bevel and straight bevel gears are available. Custom gears are made for off angle and special ratio designs. Curtis Machine designs and produces spiral and straight bevel gears in house. With in house production quality and availability can be controled. Spiral bevel gears are quieter, provide more torque density, and can be ran at higher RPM's than straight bevel gears. Straight bevel gears maintain a cost advantage in many cases.

Whether you need a 1:1 ratio, a 6:1 ratio reducer, a 1:6 ratio speed up gearbox or something in-between Curtis Machine can design and produce what you need. Flanges can be made right into the housing or added on as a cap. NEMA, SAE and custom flanges can be designed in as an integral part of your housing. Torque capacities range from 10 inch pounds to 40,000 inch pounds. Splined, keyed and hollow bore shafts are available.

Below is a listing of Curtis Machine's single reduction options. For more information on double reduction and shifting gearbox options please contact the factory.

MAKE IT THE BEST, MAKE IT A CURTIS.

|

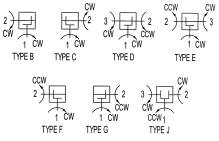

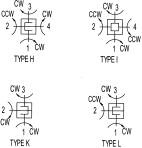

·Clockwise

(CW) and counter-clockwise (CCW) notations indicate the direction of rotation

when facing that end of the shaft extension.

·Arrows

shown on the drawings are over the top of shaft extensions.

·The

numbers shown adjacent to the shaft extensions are used to designate specific

extensions when ordering.

·Shaft

arrangements will also operate in the opposite direction as shown.

|

GEARBOX MODELS:

| FM375 | FM625 | FM750 | 150 | 175M | 200M | 200C | CCB | CSSB | FM1000 | ||

| 211 | 215 | 216 | 215H | 214 | 412M | 416M | 413 | 414 | 511 | ||

| 515 | 516 | 514 | 615MA | 616MA | 614MA | 6013 | 7050 | 9200 | CUSTOM

GEARBOXES |

||

STANDARD PARALLEL SHAFT GEARBOXES:

|

|

|

|

|

||||||||

OPEN BEVEL GEARING:

| 1.1 Straight | 1.35:1 Straight | 1.5:1 Straight | 1:1 Spiral | 1.35:1 Spiral | 1.5:1 Spiral | 2:1 Spiral | 3:1 Spiral | ||

SPUR AND HELICAL GEARS:

|

|

HELICAL GEARS | ||||

GEARBOX FLANGE OPTIONS:

|

Options |

||||||||||